Limited use of surface, is the starting point for domestic technology universal car lithium grease

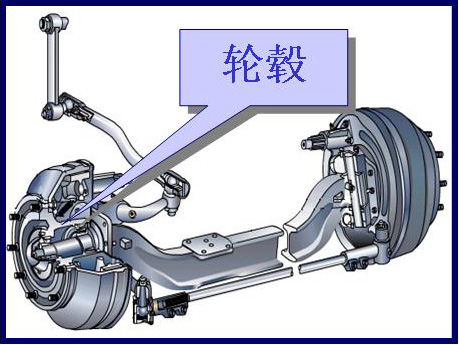

(B) the wheel hub bearing lubrication conditions are more stringent,

by the vehicle, vehicle speed, road conditions and driving influence the

climate and environment, and determines the vehicle wheel bearing

grease with the following performance requirements:

1, high temperature performance

2, the mechanical stability and performance

3, water resistance

4, low temperature performance

5, anti-rust properties

6, oxidation stability

7, long life

(C) wheel bearing grease

E103 lithium grease

Meet the general use of vehicles, life is about 30,000 km

E201 senior automotive grease

Amide resin, high temperature performance, good mechanical stability

Life than ordinary lithium grease grow 3 to 4 times, up to 100,000 kilometers

E202 extreme pressure high temperature grease

Basically meet the ASTM D 4950 GC-LB specifications

(D) wheel bearing grease parameters

(1) E103 lithium grease

Features

Excellent mechanical stability, structural stability, not thinning Loss

Excellent lubricating properties, high temperature performance and long life

Excellent rust resistance, to prevent corrosion of the metal surface friction

Technical Specifications

Meet the enterprise standard Q / SH303 242-2004

Applications

For general automotive wheel bearings, chassis, motor, pump parts of the lubrication

Use temperature: -20 ~ 120 ℃

project

Typical data

Test methods

number 2

number 3

Exterior

Red uniform and smooth ointment Red uniform and smooth ointment

Visual

Work cone penetration, 0.1mm

274

233

GB/T 269

Dropping Point, ℃

197

199

GB/T 4929

Corrosion (T2 copper, 100 ℃, 24h)

qualified

qualified

GB/T 7326

Steel mesh oil (100 ℃, 24h),%

4.1

1.1

SH/T 0324

Corrosion (52 ℃, 48h), level

1

1

GB/T 5018

No. (2) E201 advanced automotive grease

Features

Excellent oxidation stability performance, high temperature grease to prevent deterioration

Excellent mechanical stability and performance with a suitable adhesive, to avoid loss of grease

Excellent high temperature performance, to ensure the normal operation of the bearing a wide temperature range

Good resistance to water washout resistance, suitable under wet conditions bearing lubrication

Good lubricity, reducing bearing wear protection

Excellent overall performance, to ensure a longer bearing life

use

This product is suitable for all types of automotive wheel bearings, pumps, motors, fan bearings and chassis and other parts of the lubrication, also suitable for industrial lubrication of high temperature and long-life components bearing

Temperature range: -30 ℃ ~ + 150 ℃

project

Typical data

Exterior

Red uniform ointment

Dropping Point, ℃

320

Cone penetration (0.1mm)

263

Extend the working cone penetration (thousands of times)

310

Stencil oil, (100 ℃, 3h),%

3.2

Evaporation (100 ℃),% (m / m)

0.3

Similar to the viscosity (-20 ℃, 20S-1), Pa.s

995

Chemical stability, pressure drop, Mpa,

0.00

Water washout resistance (79 ± 2 ℃),%

4.38

(3) No. E202 extreme pressure lithium complex grease

Features

Excellent oxidation stability performance, high temperature grease to prevent deterioration

Excellent mechanical stability and performance with a suitable adhesive, to avoid the loss

Excellent high temperature performance, to ensure the normal operation of the bearing a wide temperature range

Good resistance to water washout resistance, suitable under wet conditions bearing lubrication

Good lubricity, reducing bearing wear protection

Excellent overall performance, to ensure a longer bearing life

use

The industry high temperature, medium, heavy ball, roller bearing lubrication

Temperature range: -30 ~ + 150 ℃, short-term can be used to + 180 ℃

project

Typical data

試驗方法

No. 1

No. 2

No. 3

Work cone penetration, 0.1mm

330

282

240

GB/T269

Extend the working cone penetration rate of change (100,000),%

7.1

10.1

11.2

GB/T269

Dropping Point, ℃

270

280

295

GB/T3498

Corrosion (T2 copper, 100 ℃, 24h)

1b 1b 1b

GB/T7326

Steel mesh oil (100 ℃, 24h)%

5.26

2.04

0.11

SH/T0324

Water washout loss (79 ℃, 1h),%

2.45

2.22

2.13

SH/T0109

Oxidation stability test (99 ℃, 100h, 0.770MPa, pressure drop, MPa

0.035

0.035

0.035

SH/T0325

Similar to the viscosity (-10 ℃, 10s-1), Pa · s

397.1

642.3

1041.2

SH/T0048

Four-ball test, PD, N

3089

3089

3089

SH/T0202

Extreme pressure performance (Timken Method) OK value, N

200

200

200

SH/T0203

Base oil kinematic viscosity (40 ℃, mm2 / s)

236.8 236.8 236.8

GB/T265